Antifriction

Lubricants and more effective treatments on the market

All lubricants contain additives to enhance the performance of the base oil and prevent premature wear, regardless of whether the oil is mineral, synthetic, or semi-synthetic.

The Prolab antifriction treatment provides superior performance in two distinct ways :

- By enhancing the properties of additives added to the base oil

- By eliminating friction between metal parts

Enhanced Additive Action

Lubricants contain additives such as antifoaming agents, ash dispersants, detergents, antioxidants and anticorrosives, pour point depressants, viscosity index improvers, and antiwear agents. These additives are essential because without them the lubricant quickly becomes ineffective. Performance differences between the various lubricants on the market boil down to differences in the quality and quantity of additives as well as the quality of the base oil.

All Prolab lubricants, engine oils, greases, and specialty lubricants are high-end products. Prolab uses only superior quality base oils and the very best additives in greater quantities than the competition.

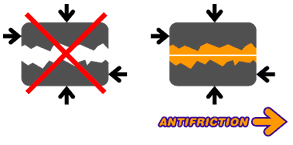

Elimination of Metal-to-Metal Friction

The Prolab antifriction treatment contains exclusive antifriction agents. It coats metal parts with a polarized film that penetrates the pore structure of metals, eliminating metal-to-metal contact. This lubricating film performs superbly under extreme pressures and is resistant to contaminants.

It makes engine operation quieter, smoother, and more economical. Starting becomes easier, especially in cold weather. Remember that when the engine stops, oil settles in the bottom, leaving metal parts unprotected. When you start the engine again, it takes a while for the oil to cover metal parts again for protection.

The Prolab antifriction film is permanently there to prevent metal-to-metal contact while the lubricant rises to play its role.

Prolab, Trailblazer and Leader in Antifriction Technology

Antifriction treatment is a recognized technology with an increasingly vital role to play in today's new generation of engines. Antifriction agents are one of the keys to improving fuel consumption and reducing pollution.

Prolab is a trailblazer in the field. Independent tests have shown that Prolab's exclusive formulation far outperforms competing products.

PL-100 and GS-1000, Two Prime Examples of the Prolab Edge

Prolab's PL-100 is a multipurpose super lubricant/penetrant with antifriction treatment. Subjected to the standard wear and load resistance test under the same conditions as the most popular brand on the market today, PL-100 with antifriction treatment showed 6 times more load resistance and half as much wear.

Standard ASTM D2783 four-ball test: A moving steel ball exerts pressure on three stationary balls coated with the lubricant being tested. The load is increased until the balls block and the wear of the steel is measured.

Prolab's GS-1000 is a synthetic grease with antifriction treatment. Subjected to the high temperature ball bearing life test under the same conditions as conventional greases, GS-1000 remained effective at least 3 1/3 times longer than the others.

Standard ASTM D3336 test: The grease is used in a ball bearing rotating at 10,000 rpm at a temperature of 180 °C.

Prolab Keeps Its Promises

The mere presence of additives in a lubricant does not guarantee actual performance. The quality of the formulation is paramount. Prolab produces only high-performance lubricants with premium base oils and uses the best additives, in greater quantities than conventional lubricants.

The Prolab promise: lubricants that offer you the very best value for your money.